- HOME

- What is Rubber Grinding Stone?

What is Rubber Grinding Stone?

What is Rubber Grinding Stone?

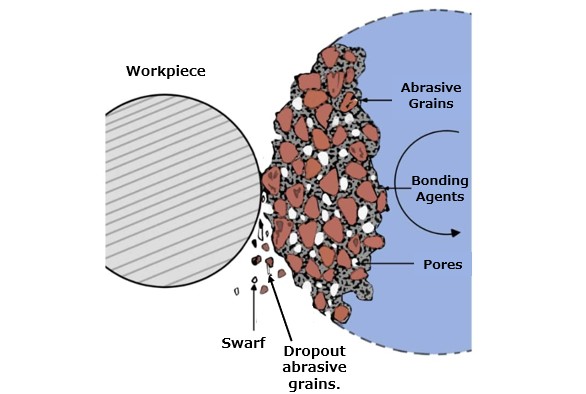

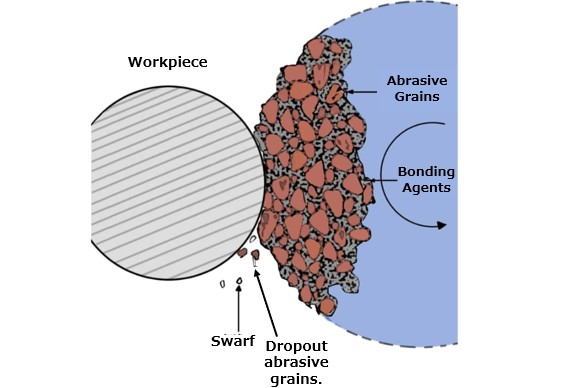

Basic components of a grinding stone

- Abrasive grains

- Bonding agent

- Pore

A rubber grinding stone is a type of grinding stone that uses rubber as the bonding agent for its abrasive grains.

While conventional grinding wheels typically require two separate wheels and multiple steps—one for grinding and another for polishing—a rubber grinding stone can simultaneously grind and polish while absorbing impact, thanks to its ability to deform according to the workpiece.

Furthermore, due to the excellent autogenous action of rubber elasticity, clogging common in conventional grinding wheels is minimized, making dressing (reshaping) almost unnecessary.

Our proprietary abrasive grain design provides sharp cutting performance, while the rubber elasticity ensures uniform polishing marks, enabling a wide range of processes from grinding, polishing, deburring, to final finishing. This contributes to improved manufacturing efficiency and cost reduction.

Differences Between Rubber Grinding Stones and Conventional Grinding Stones

Rubber grinding stones have no pores, resulting in minimal detached abrasive grains and swarf

Conventional grinding stones (with pores)

Rubber grinding stones (no pores)

Advantages of Rubber Grinding Stones

- Can be used on a wide range of materials, including hard-to-machine metals, high-hardness brittle materials, rubber, and resins.

- Can operate at low rotational speeds, generating less heat and reducing the load on the workpiece.

- Rubber elasticity reduces the likelihood of polishing scratches compared to resinoid or vitrified grinding wheels.

- Simultaneously achieves grinding and polishing, enabling process reduction.

- Resists clogging and typically requires no dressing.

- Provides uniform polishing due to rubber elasticity, minimizing polishing marks.

- Easy truing allows operators to quickly and freely adjust the grinding stone shape.

- Conforms well to the workpiece, reducing vibration and enabling precise work.

- Minimizes over-grinding and uneven work.

- The rubber bonding agent reduces dust generation from the grinding stone.

| Element | Conventional Grinding Stone | Rubber Grinding Stone |

|---|---|---|

| Abrasive grains | A, WA, C, GC, Ceramic, Diamond, etc. | |

| Bonding agent | Resinoid, Vitrified, Electroplated, Metal, etc. | Rubber |

| Pores | Yes | No (self-sharpening action removes swarf) |

About Cutting, Grinding, and Polishing with Rubber Grinding Stones

In metalworking, there are three main types of processes: cutting, grinding, and polishing. Rubber grinding stones excel particularly in grinding and polishing.

What is cutting?

Cutting is a method of shaping a material by removing material with a cutting tool.

Cutting includes processes such as turning, milling, and drilling. In cutting, the cutting edges of the tool penetrate the material surface to remove material, allowing relatively large amounts of material to be removed.

What is Grinding?

Grinding is a method of shaping a material by abrading it.

Grinding uses ultra-hard abrasive wheels to remove material from the workpiece surface, smoothing it. Common methods include surface grinding, cylindrical grinding, internal grinding, and external grinding.

Grinding is used for precision components or parts requiring a fine surface finish, enabling high-accuracy surface results.

What is Polishing?

Polishing is a method of shaping a material by abrading and smoothing its surface.

The abrasive is applied to a tool, and friction removes material from the workpiece surface, smoothing it and achieving a fine surface finish.

Polishing is used for softer materials or for high-precision parts that require excellent surface finishing.

Methods include hand polishing, machine grinding, ultra-precision polishing, and micro-machining.

Characteristics of Rubber Grinding Stones

Definition of Rubber

Rubber is a material that exhibits elastic deformation.

Elastic deformation: the property of stretching or compressing significantly in the direction of applied force and returning to its original shape when the force is removed.

Molecular chains are entangled with one another.

Mechanism of Elastic Deformation in Rubber

- Rubber consists of long, flexible chains called polymer chains

- The polymer chains are entangled with each other, forming spherical coils (random coils)

- These coils deform under small forces and return to their original shape when the force is removed

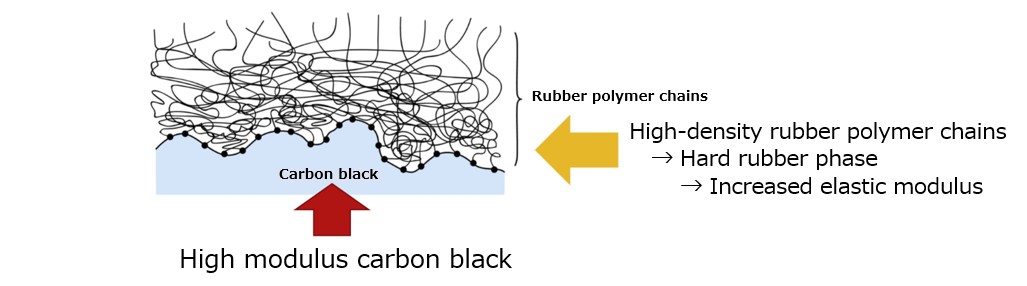

Mechanism of Strength Enhancement in Rubber

Types of Raw Rubber

Raw Rubber

Natural Rubber

A product obtained by drying and solidifying the latex secreted by several types of rubber trees

- Excellent mechanical properties

- A natural material that protects the global environment

Synthetic Rubber

A product with a chemical structure obtained industrially from petroleum

- Rubber with a variety of properties

The usage amounts of natural and synthetic rubber are roughly equal.

Applications of Rubber

| Type of Rubber | Applications | Abbreviation |

|---|---|---|

| Silicone Rubber | Gaskets, defoaming, automotive parts, medical and food-related applications | Si,Q |

| Fluoro Rubber | Seals for heat exchangers, gaskets for sanitary pipes, seals for dry cleaning equipment | FKM |

| Natural Rubber | Automotive tires, hoses, belts, air springs | NR |

| Isobutylene Rubber | Automotive tires, hoses, belts, air springs | IR |

| Chloroprene Rubber | Automotive parts, conveyor belts, adhesives, window frames, rubber coatings | CR |

| Nitrile Butadiene Rubber | O-rings, gaskets, oil sheets, oil-resistant hoses | NBR |

| Ethylene Propylene Diene Rubber | Automotive bumpers, industrial and construction rubber products, high-voltage rubber cables | EPDM |

| Butadiene Rubber | Tires, footwear, vibration-damping rubber, plastic modifiers, belts | BR |

| Butyl Rubber | Tire inner tubes, speaker components, halving, window frame rubber | IIR |

| Styrene-Butadiene Rubber | Floor tiles, footwear, battery cases, automotive tires | SBR |

Types of Raw Rubber

How Silicone Rubber Products Are Made!

There are various other manufacturing methods for rubber as well.

Processing Steps of Silicone Rubber

Raw Material

1. Compounding

2. Rolling

3. Cutting

4. Molding

5. Final Inspection

6. Secondary Vulcanization

Completion

About Abrasive Grains

Abrasive grains are high-hardness granular or powdered materials that serve as the main cutting edges during the grinding of workpieces.

When mixed with a bonding agent, shaped, and sintered, they become a "grinding stone."

Abrasives are classified into three types: 1) Alumina-based (Aluminum Oxide), 2) Silicon-based (Silicon Carbide), and 3) Superabrasive (Diamond).

Main Types of Abrasive Grains

| Category | Symbol | Type | Characteristics |

|---|---|---|---|

| Alumina-based | A | Brown Alumina Abrasive | Mainly composed of corundum crystals with titanium oxide in solid solution, giving it a brown color. Slightly softer than other abrasives but very tough, suitable for free grinding (double-ended grinders) and general copper grinding. |

| WA | White Alumina Abrasive | White in color with over 99% alumina purity and minimal impurities. Harder than A but less tough, so the grains micro-fracture during use, maintaining sharpness, making it suitable for grinding relatively hard materials such as alloyed, tool, or hardened copper. | |

| PA | Pink Alumina Abrasive | Refined by the Bayer process with added chromium oxide and, if necessary, titanium oxide, melted in an electric furnace, solidified, crushed, and granulated. Tougher and harder than WA, with excellent shape retention, long dressing cycles, and low grinding heat, suitable for hardened and tempered copper. | |

| HA | Fused Alumina Abrasive | Made from bauxite or Bayer-processed alumina, melted and solidified in an electric furnace, crushed and granulated. Mainly composed of single-crystal corundum. | |

| AE | Artificial Emery Abrasive | Alumina material from bauxite, melted and reduced in an electric furnace, solidified, crushed, and granulated. Composed mainly of corundum and mullite crystals, gray-black overall, high hardness with moderate toughness, with a unique crystalline structure providing self-sharpening. | |

| Z | Alumina-Zirconia Abrasive | Premium abrasive made by melting high-purity zirconia and alumina above 2500°C. Suitable for polishing copper, cast iron, heat-resistant copper, titanium, nickel alloys, aluminum alloys, titanium alloys, tungsten, etc. High hardness and toughness. | |

| Silicon-based | C | Alumina-Zirconia Abrasive | Black in color with over 95% silicon carbide purity. Harder than A or WA but less tough. Unsuitable for steel grinding due to rapid wear and dull finish, but suitable for aluminum alloys, copper alloys, non-ferrous metals, cast iron, hard brittle materials, and carbide grinding. |

| GC | Green Silicon Carbide Abrasive | Made from silica and coke reacted in an electric resistance furnace, crushed and granulated. Over 99% pure silicon carbide, high hardness but low toughness, suitable for grinding extremely hard materials such as carbide and special cast iron. | |

| Diamond-based | D | Carbon |

*WA-CM: Abrasive grains specially processed by our company

About Bonding Agents

A bonding agent is an adhesive (bond) used to bind and hold abrasive grains together.

Main Types of Bonding Agents

| Type | Symbol | Characteristics |

|---|---|---|

| Vitrified | V | Has strong holding power for abrasive grains, applicable to a wide range of work materials—from carbon steel and alloy steel to precision and high-efficiency grinding—and offers excellent grinding performance and relatively long life. |

| Resinoid | B | A bonding agent mainly composed of phenolic resin. Compared with vitrified bonds, it has greater elasticity and is suitable for a wide range of applications from rough to finish grinding. |

| Rubber | R | A rubber-based bonding agent with high elasticity and excellent resistance to impact. It offers superior grinding and polishing performance, and its unique rubber elasticity produces a comparatively fine and smooth surface finish. |

| Electroplated | P | A nickel-based bonding agent in which abrasive grains are fixed onto a metal base by electroplating. With a large protrusion of abrasive grains, it provides excellent performance for rough grinding that requires sharp cutting ability. |

| Metal | M | A metal-bond type in which abrasive grains are firmly fixed onto a metal base, providing strong grain retention and excellent heat and wear resistance. It offers minimal shape deformation due to wear, larger grain protrusion than electroplated bonds, and outstanding performance in grinding materials prone to clogging. |