- HOME

- Product Lineup (Search by Series)

- Other Types

Other Types

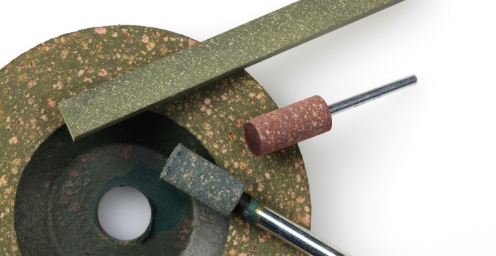

For a wide range of polishing and grinding needs — <Daiwa Rabin>

Daiwa Rabin products are used in various manufacturing fields for a wide range of operations.

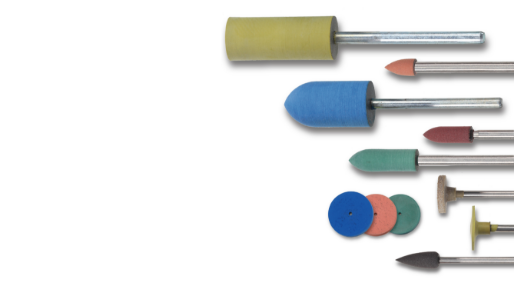

With a wide product lineup, you can select the most suitable rubber grinding stone according to the material, polishing area,

and desired surface finish of the workpiece.

In addition, we meet various polishing needs by customizing abrasive type, shape,

and dimensions to suit customer requirements.

Product Lineup

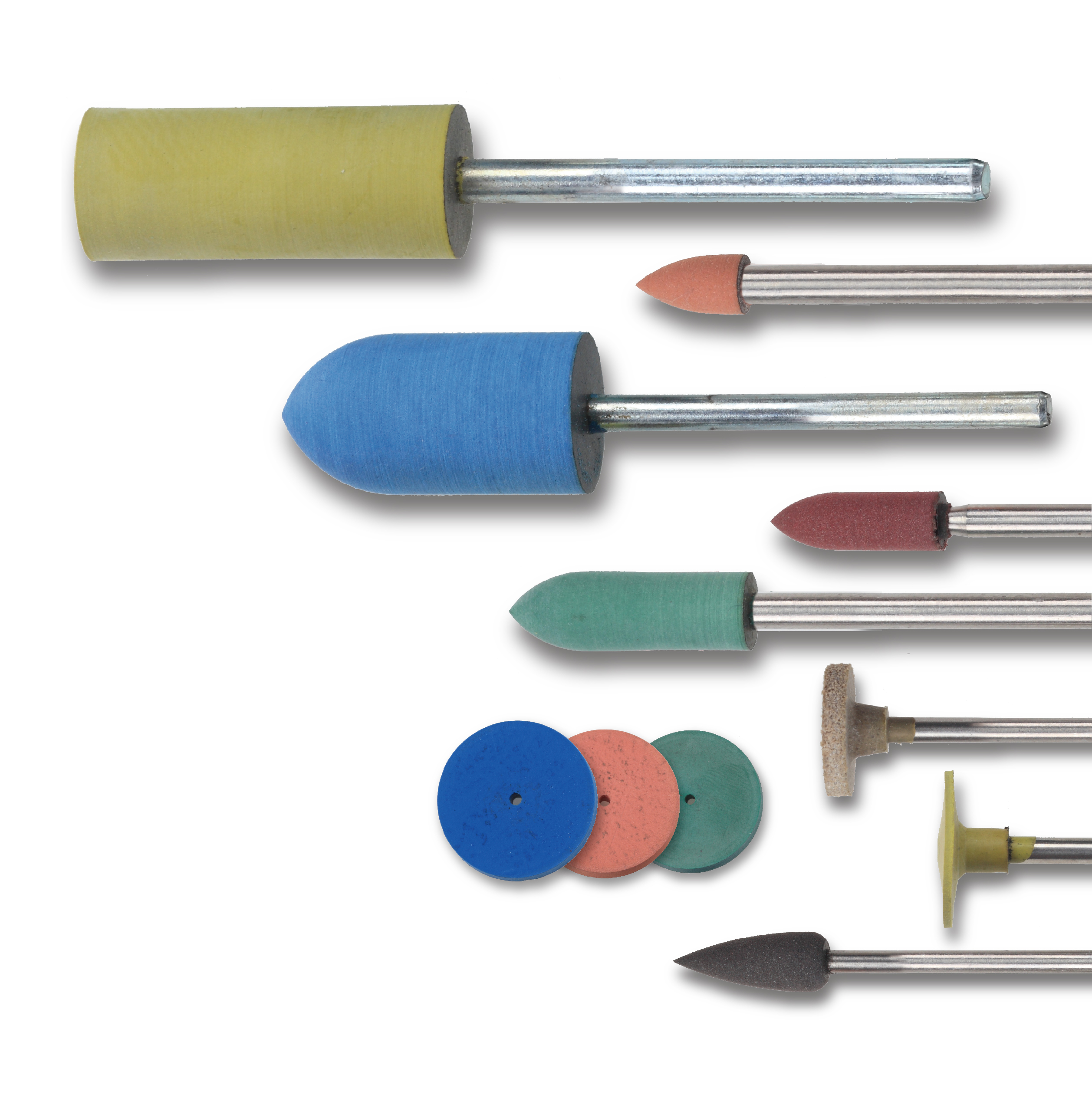

Features

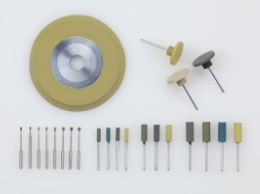

A unique rubber formulation and specially blended abrasives tailored to the polishing process provide a wide lineup, including soft types that conform easily to the workpiece and hard types designed for efficient operation.

Applications

・Polishing of precision instruments

・Polishing of precious metals and jewelry

Grit Size

46、200、400、3,000

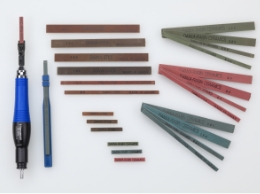

Features

・Improves work efficiency and significantly enhances the working environment when used in combination with a buff during polishing.

・Light work on curved surfaces.

・Removal of polishing marks and fine scratches.

・Correction of casting surface, etc.

Applicable Materials

General steel, stainless steel, aluminum, copper, etc.

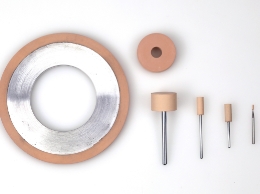

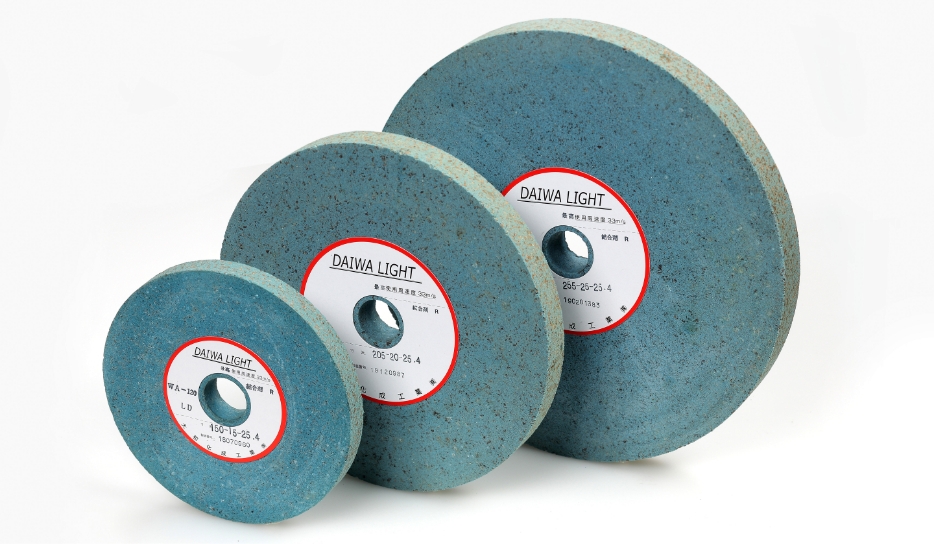

Features

・Conventional rubber grinding stones have rotational speed limitations, but Daiwa Light is lightweight, eliminating these speed restrictions.

・Can be used universally from hard-to-cut materials to non-ferrous metals.

・The foamed, porous structure reduces clogging and polishing heat, allowing continuous polishing.

・The elastic binder prevents deep scratches and achieves a uniform finish.

・Usable in both dry and wet conditions.

Typical Applications

・Polishing after bead cutting

・Removal of parting lines and machining burrs

・Removal of various metal machining marks

・Polishing and rust removal after hardening

・Surface finishing before buffing or plating

Abrasive Grains

WA (Our uniquely developed abrasive grain)

Features

A product made using our proprietary silicone rubber formulation.

Applies minimal load to the workpiece and allows finishing without burning.

*Wheel type only, size limited

*For details, please contact us.

Features

Ultra-fine diamond particles are incorporated into silicone rubber, providing high performance on resin and zirconia.

Applications

Intermediate finishing of resin, metals, and precious metals.

Abrasive Grains

D (Diamond)

We accept inquiries for custom-made products

We develop custom-made products according to customer requests. With our excellent technical expertise and rapid development capabilities, we can meet various needs. Please feel free to consult us about custom-made development.